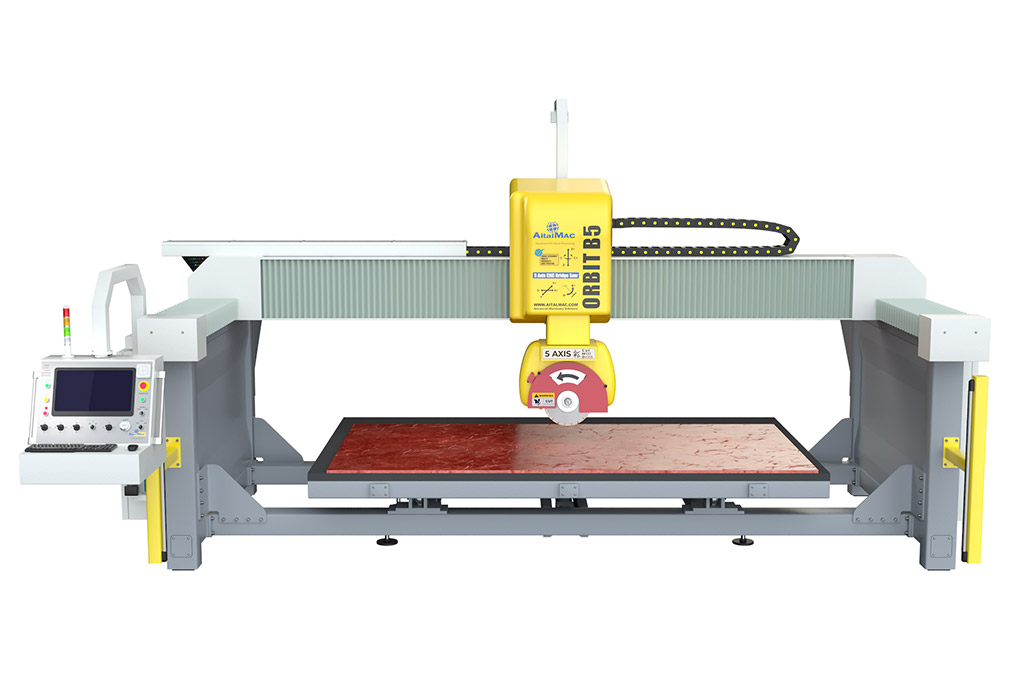

5 axis CNC Bridge Saw Orbit B5

This bridge saw has everything a technologically advanced bridge saw needs to have today: spindle with half inch fitting with trough-spindle lubrication, on-board camera, blade presetting and stone thickness probe.This machine is a fully interpolated 5 axis bridge saw. Head rotate 0° to 400° interpolate with blade tilting 0° to 90° makes it suitable for any jobs . This machine can runs large production , at the same time containing costs.

The absolute precision of the movements is guaranteed by a state of art transmission on linear ball guide, moved by brushless motors through high precision helical gears and racks.

This machine comes with the “absolutely zero” technology, which allows the machine to work without doing the homing process.

It has an extremely easy to use interface, designed to facilitate easy interaction between operator and machine.

The ORBIT B5 imports and works with DXF (standard CAD file) f and standard G-Code ( Standard RS-274 machine tool programming language), but can also do simple cuts in manual mode.

The structure is hot-galvanized and painted to last a long life.

CNC CONTROLLER & Software

Easy to use interface. Imports and works with DXF files and standard G-Code, but can also do simple cuts in manual mode.

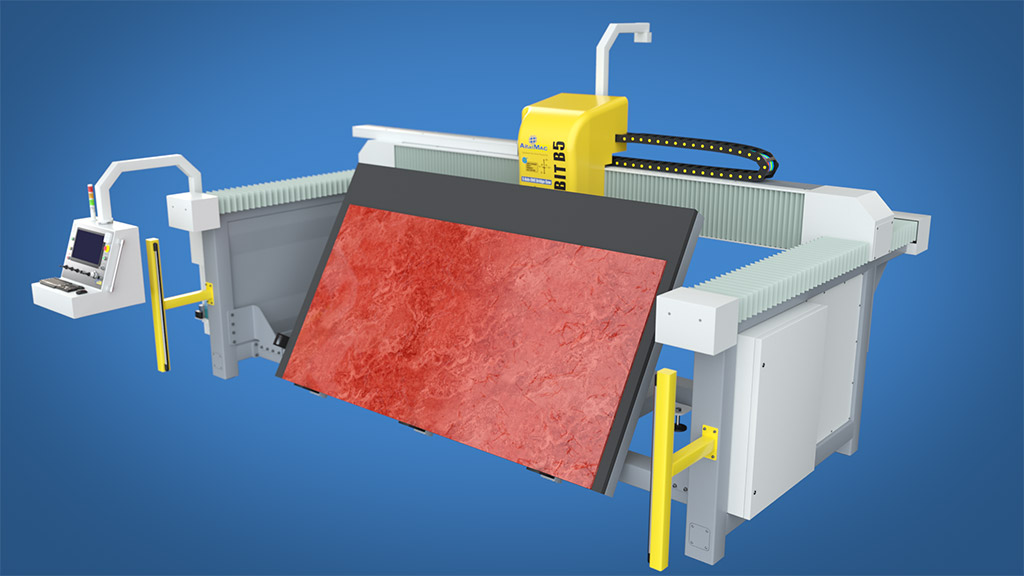

Tilting table up to 85°

Table tilts up to 85°, enabling the easy loading of your slabs.

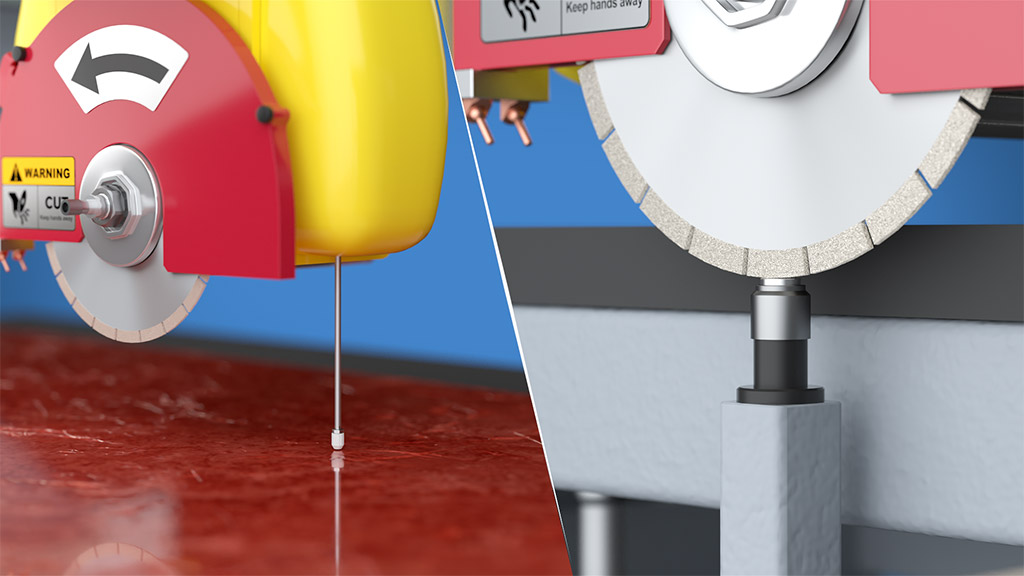

5 axis cutting head

Can miter and interpolate in any direction .

Stone & Blade probe

The stone probe and blade probe enable the machine to process the stone more accurately.( Stone probe is optional )

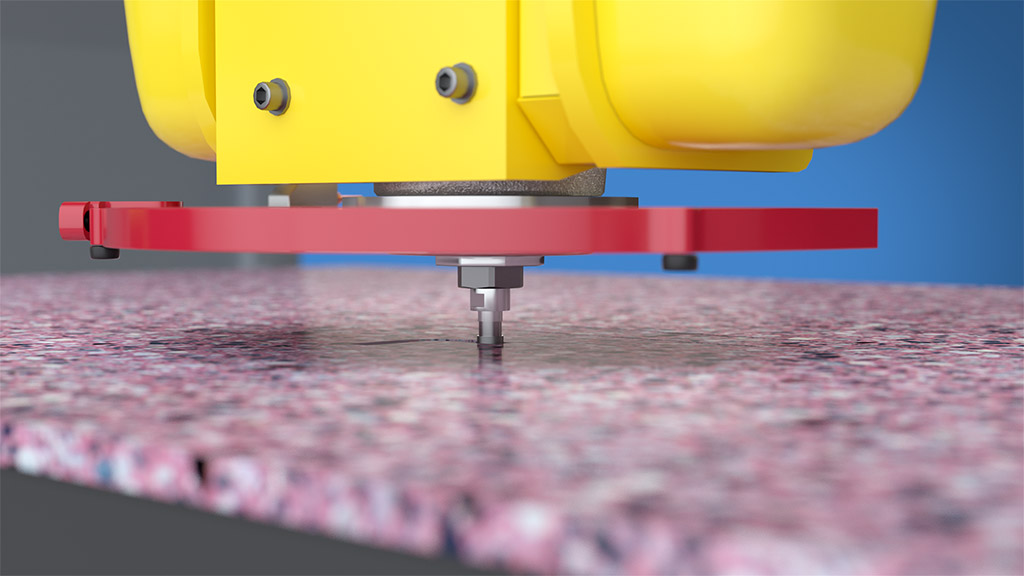

Spindle with half inch fitting

1/2” GAS fitting with internal water for fingerbits, engraving, polishing and drain boards. .

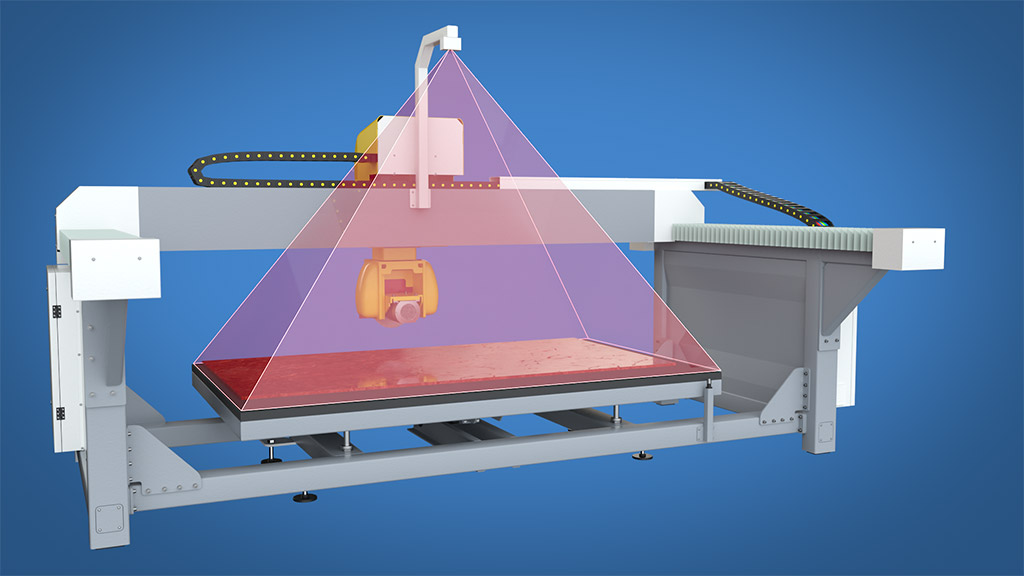

On-board camera

4K camera brings more high-definition images, which can provide high precision stone processing. The machine is supplied with an on-board camera with a precision of +/- 5mm. With the camera is possible to snap a picture of the slab, and then import the picture in the program to place your parts avoiding defects

AITEK 9 AXIS CNC CONTROLLER:

- Automatic updates trough internet

- Direct error report to AitalMAC

- Direct connection for remote assistance

- Tool manager

- Tool compensation management

- Backlash compensation

- Self-diagnosis system

- Access to driver for Aitalmac assistance

- Online monitoring system

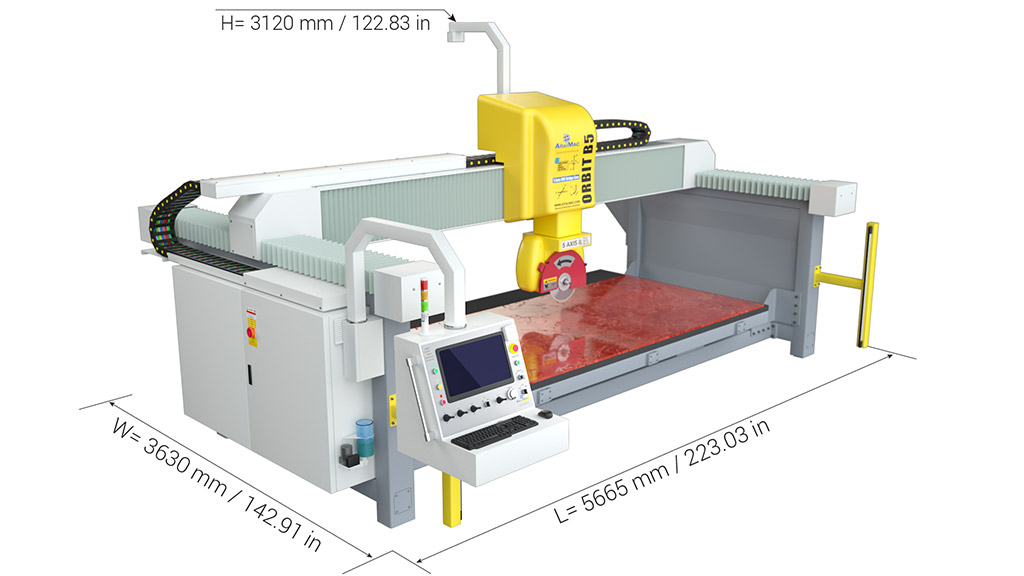

Technical sheet

| Overall dimensions | 5665x3630x3120 mm/143x223x123 in |

|---|---|

| Total weight | 5500 kg/12125 lbs |

| Max. Install power | 18 kW |

| Table size | 3400×2000 mm/134×79 in |

| Linear axis travel (X-Y-Z) | 3570-2440-300 mm/141-96-12 in |

| Rotary axis travel (B-C) | 90° - 380° |

| Max linear speed (X-Y-Z) | 26-26-7.5 m/min / 85-85-24 ft/min |

| Max rotation speed (B&C) | 3600 °/min |

| Maximum blade diameter | 500 mm / 20 in. (600 mm / 24 in. Optional) |

| Cutting disc hole diameter | 50 mm /1.96 in |

| Cutting disc flange diameter | 200 mm / 7.87 in. |

| Max cut thickness vertical | 150 mm / 6 in. |

| Electric spindle power | 11kW (s6) |

| Maximum spindle rotation | 6000 rpm |

| Air pressure required | 7 bar |

| Water consumption | 15~25 l/min / 4~6.5 gal/min |