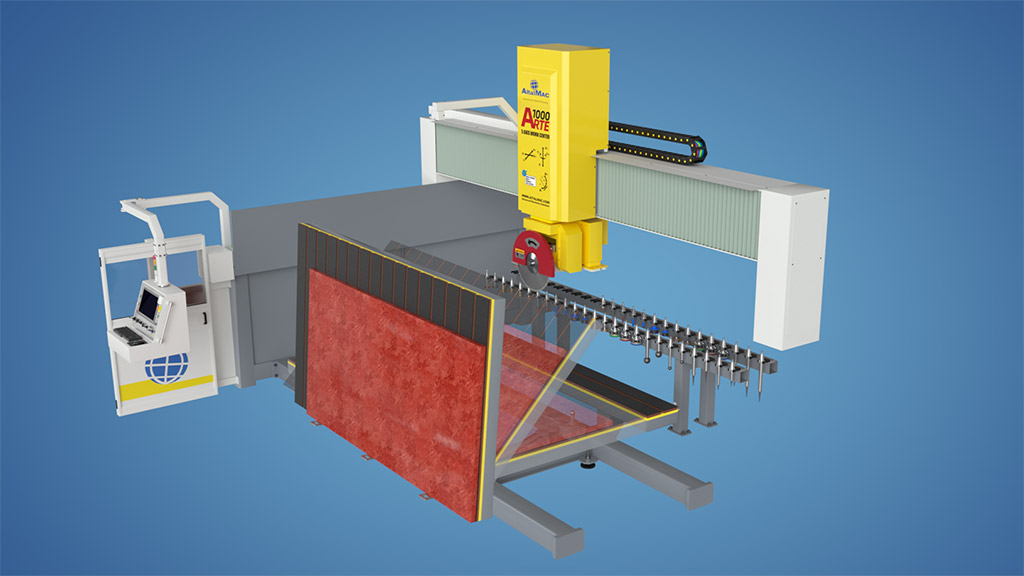

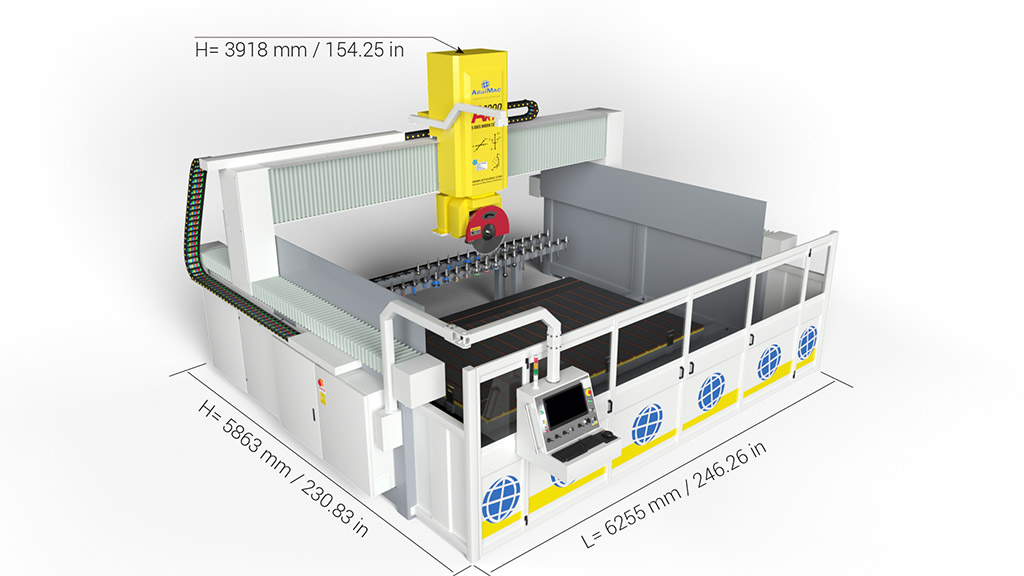

5 Axis CNC Stone Work Center ARTE1000

This 5 axis CNC stone working center is the complete package, a bridge saw and a CNC all in one, it’s equipped with everything a full-fledged work center needs, ARTE1000 5 axis work center includes functionality of a 5axis bridge saw and a 5 axis CNC router, among them: 5 interpolated axis, spindle with automatic tool change ISO40 ( ISO 50 optional ), able to reach a maximum of 9000(14000 RPM, with trough-spindle lubrication, up to 50 tool change positions, tilting table up to 85°(Optional), vacuum manipulator system for parts movement during automatic cut process, on-board camera, blade presetting and stone thickness probe, dynamic tool wear compensation, and real time adjustment of tool wear compensation.The machine in details

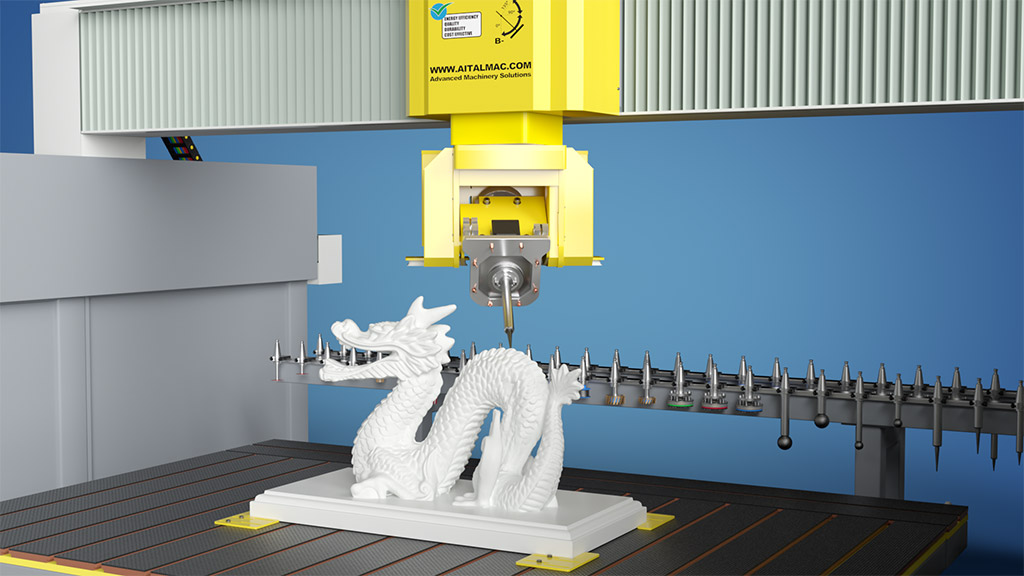

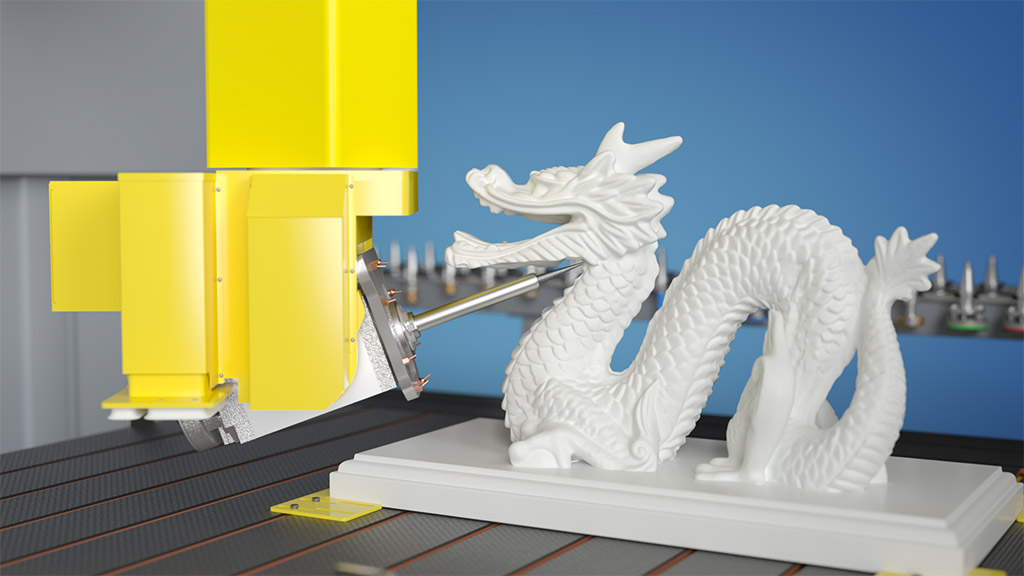

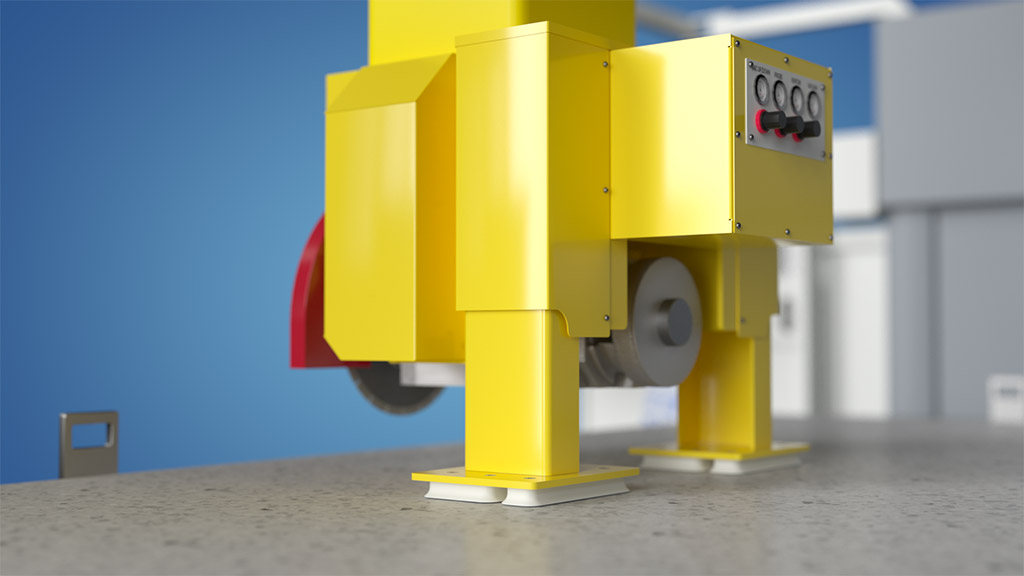

This machine is a fully interpolated 5 axis work center. The Y axis is moved by a gantry system. This guarantees a perfect square of the bridge. Automatic head rotation from 0° to 400° combined with automatic blade tilting from 0° to 135° and a Z axis of 1000 mm makes it suitable shaping sculptures and polish.

The absolute precision of the movements is guarantee by a state of art transmission on linear ball guide, moved by brushless motors through high precision helical gears and racks.

CNC Work Center comes with the “absolute zero” technology, which allow the machine to work without doing the homing process.

It has an extremely easy to use interface, realized to facilitate the interaction between the operator and the machine.

ARTE 1000 work center can quickly do easy cuts in manual, the machine also can import and work with DXF (AutoCAD) files or STL 3D cad files and “G-code” (RS-274 machine tool programming language).

Like all of AitalMAC’s machines ARTE1000 is equipped with fully interpolated CNC with 5axis kinematics, this allows you to use the machine in complete safety even in manual operations and to be able to use any CAM for the generation of the G-code with limited or no expense for post processor.

The cable-drag chain and the electric cables used on the machine are purpose.

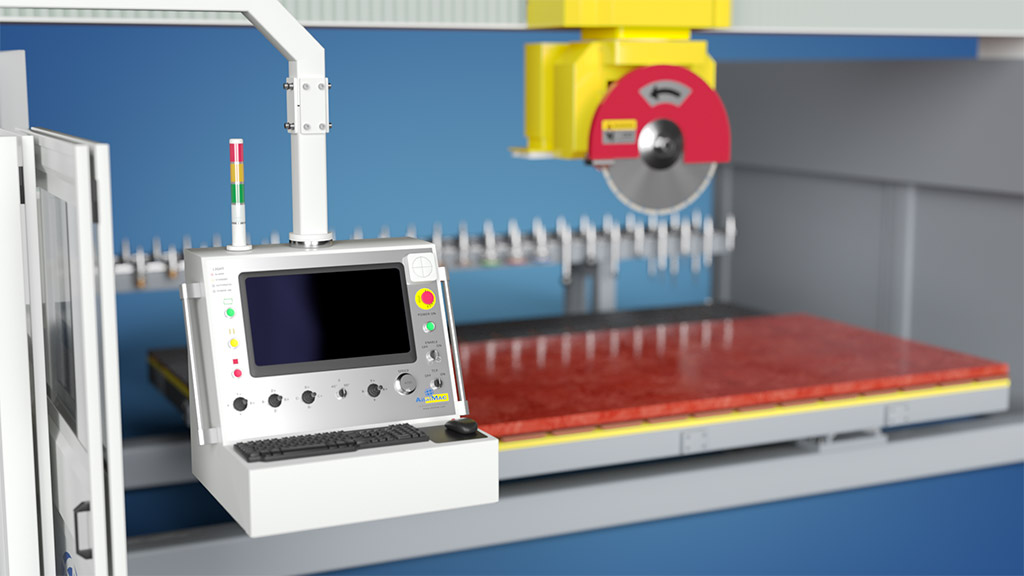

CNC Controller & Software

Easy to use interface. Imports and works with DXF files and G-Code, but can also do simple cuts in manual mode.

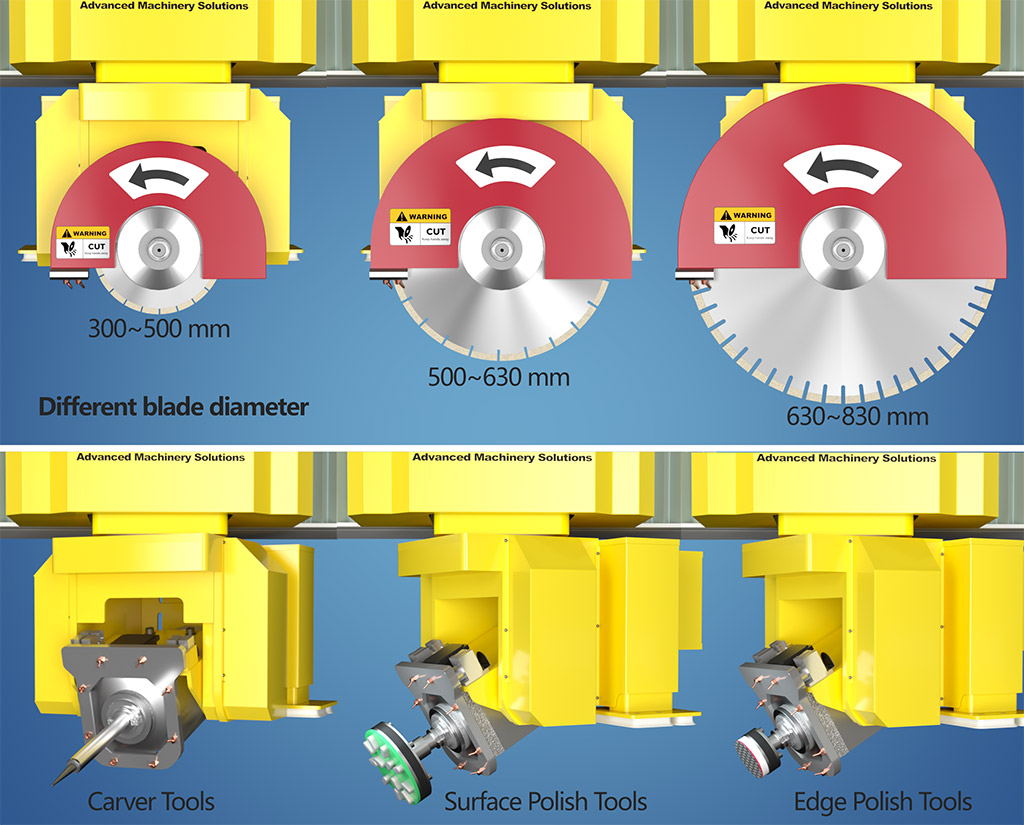

5 axis cutting head

Can miter and interpolate in any direction .

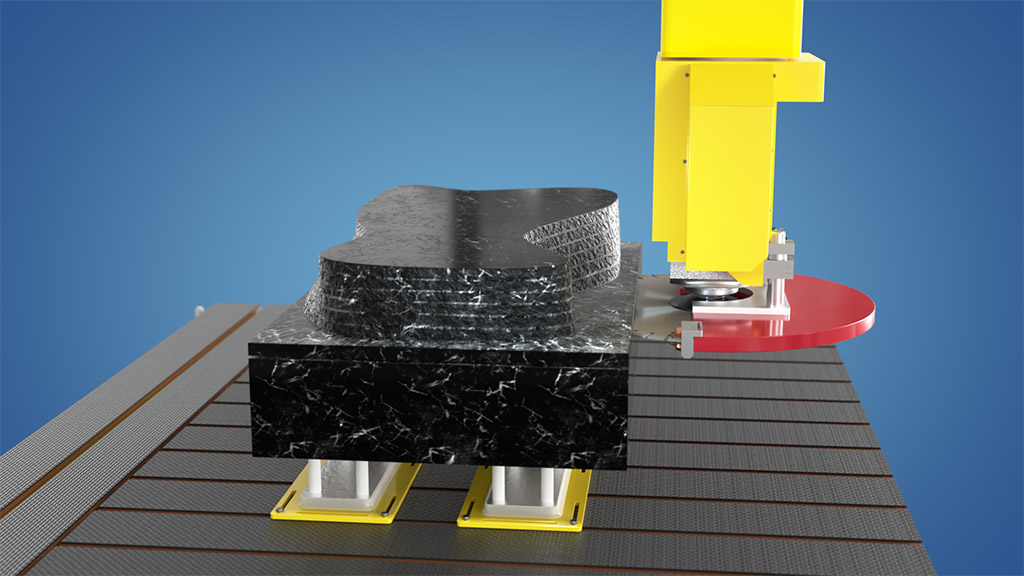

Stone carving

CNC Bridge Saw ARTE1000 accurate and fast stone carving.

Edge polish

CNC Bridge Saw ARTE1000 can polishing of flat and rounded edges of stone.

Stone surface polish

CNC Bridge Saw ARTE1000 can polish the surface of stone.

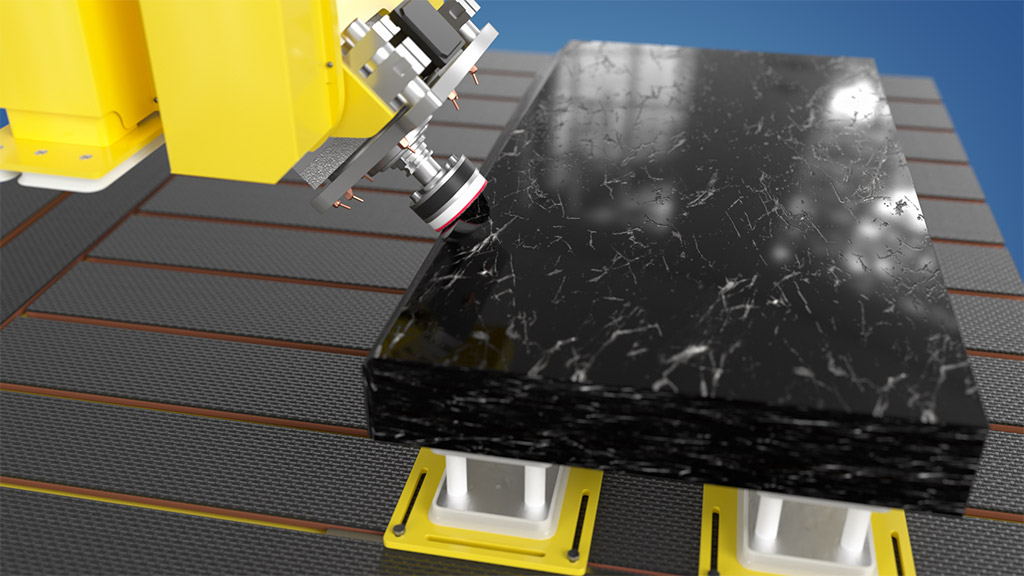

Cut before carving

Rough cutting of stone before carving can greatly improve efficiency.

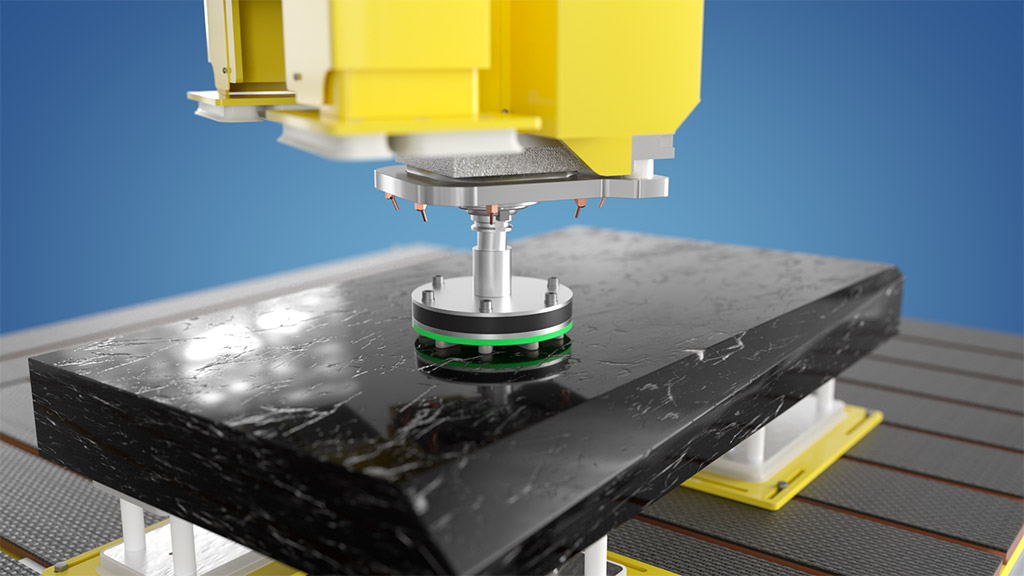

Vacuum manipulator system

The manipulator system has four vacuum cups, enabling a lift capacity of 500kg / 1100lbs.

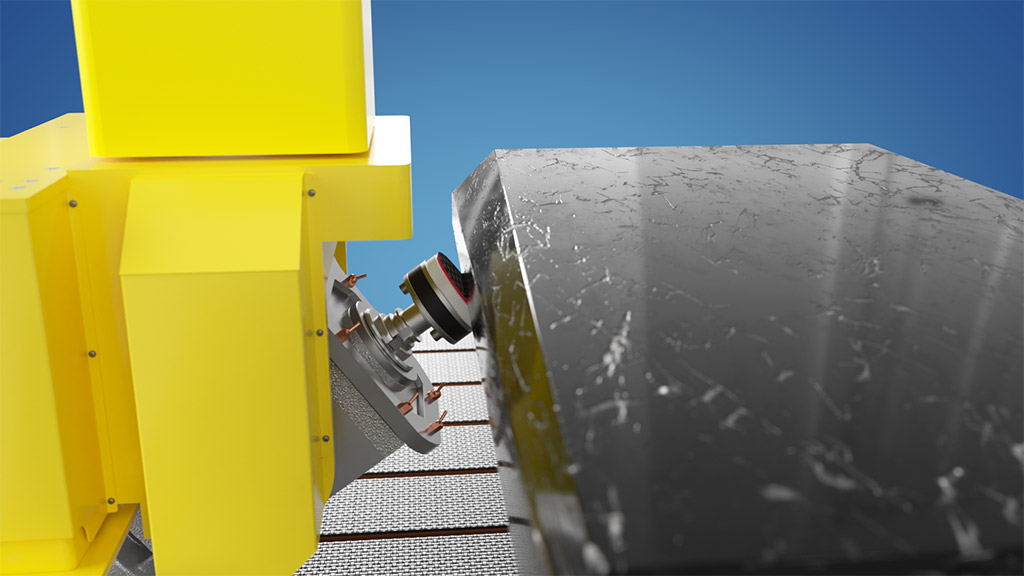

Tilting table up to 85°

Table tilts up to 85°, enabling the easy loading of your slabs.

CNC Stone Work Center

CNC Stone Work Center ARTE can install many kinds of tools, cut,carve,polish and so on.

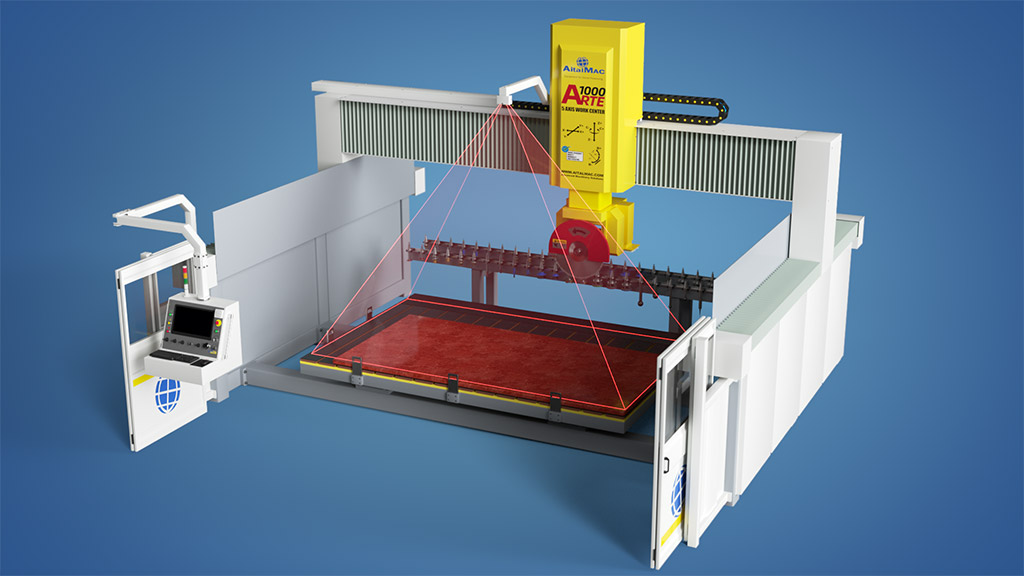

On-board camera

The machine is supplied with an on-board camera with a precision of +/- 5mm. With the camera is possible to snap a picture of the slab, and then import the picture in the program to place your parts avoiding defects.

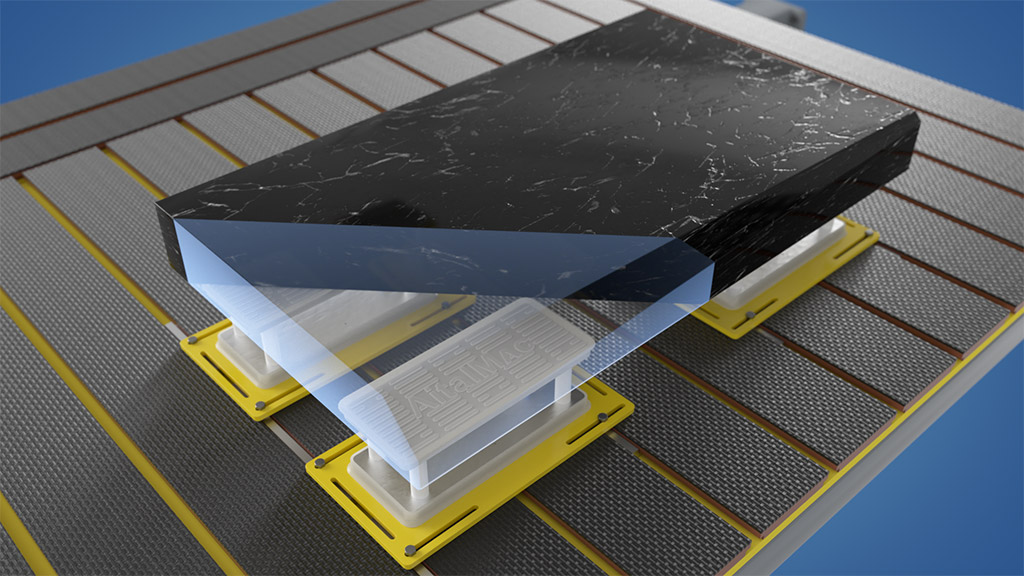

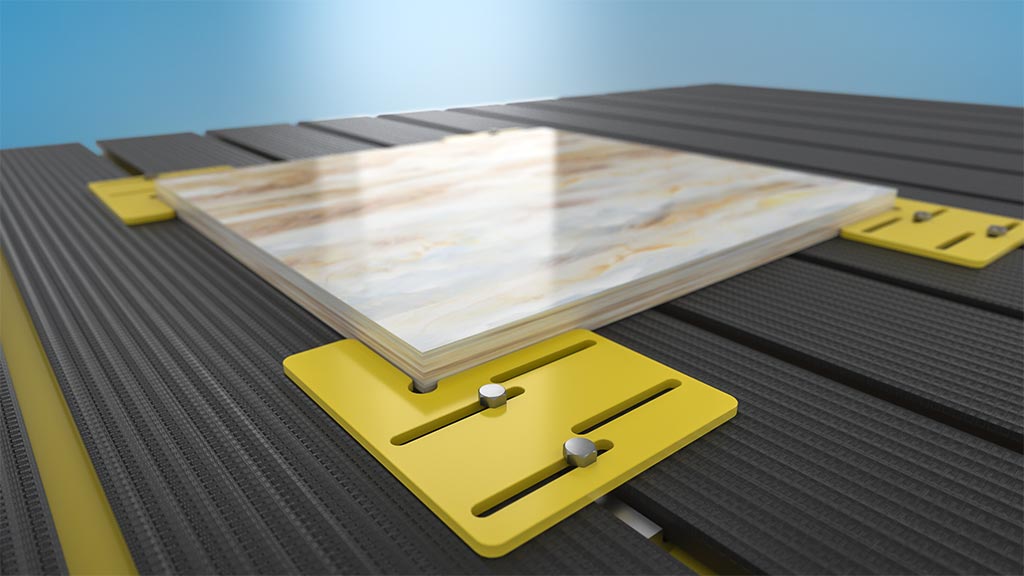

Fixture system

The table is made out of 3 layers of different materials. It’s possible to block parts using convenient fixtures (supplied with machine) that will hook on the table slots milled on the central table layer. This provides a good fixture system that allows to lock the parts on the table when doing heavy jobs.

AITEK 9 AXIS CNC CONTROLLER:

- Automatic updates trough internet

- Direct error report to AitalMAC

- Direct connection for remote assistance

- Tool manager

- Tool compensation management

- Backlash compensation

- Self-diagnosis system

- Access to driver for Aitalmac assistance

- Online monitoring system

| Overall dimensions | 6255×5863×3918 mm / 246×230×154 in |

|---|---|

| Total weight | 11000 kg/24251 lbs |

| Max. Install power | 30kW |

| Table size | 3600×2450mm/141×97 in |

| Linear axis travel (X-Y-Z) | 4060-3620-1030 mm/160-143-41 in |

| Rotary axis travel (B-C) | 135° - 540° |

| Max linear speed (X-Y-Z) | 30 -30 -7.5 m/min / 98 - 98 -24 ft/min |

| Max rotation speed (B&C) | 3600 °/min |

| Maximum blade diameter | 300~830 mm / 11.81~32.68 in |

| Cutting disc hole diameter | 50 mm /1.96 in |

| Cutting disc flange diameter | 220 mm/ 8.66 in |

| Max cut thickness vertical | 300 mm / 11.81 in |

| Electric spindle power | 22 kW (s1) |

| Tool holder cone | Cone ISO 40 |

| Automatic tool change stations | 50 |

| Maximum spindle rotation | 9000 RPM |

| Vacuum cups | 4 |

| Vacuum lift capacity | 500 kg/1100 lbs |

| Air pressure required | 7 bar |

| Water consumption | 15~25 l/min / 4~6.5 gal/min |