Kitchen Top CNC KT48

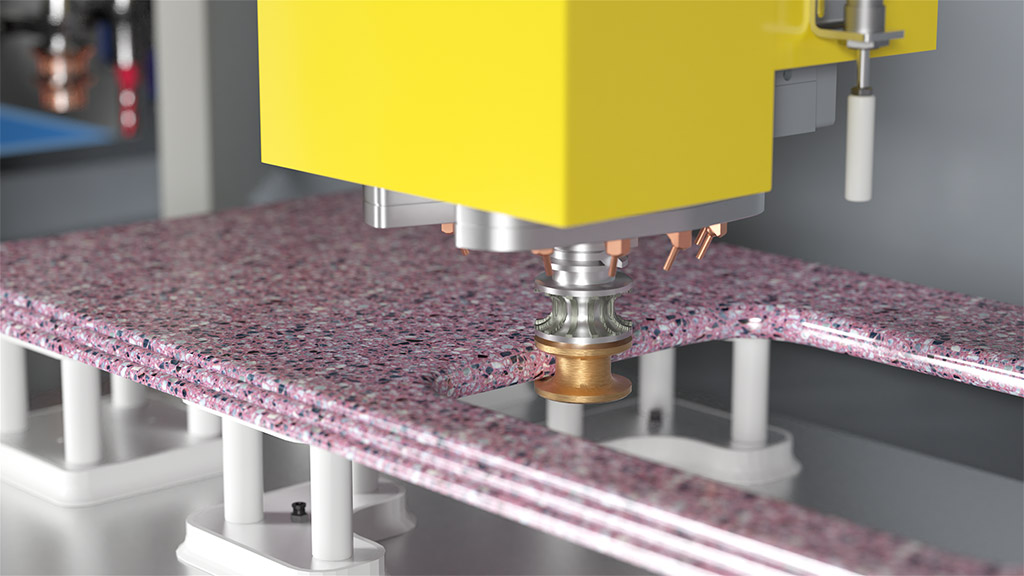

Kitchen Top CNC KT48 is a 3 Axis CNC machine with excellent performance and powerful functions, designed to be the ideal stone working center, especially thought for kitchen sink cutouts. It can complete a series of work independently, such as stone cutting, flume processing and edge polishing.Kitchen Top CNC KT48 Featured

- Kitchen Top CNC KT48 is very easy to operate, especially suitable for kitchen sink cuts, with a dedicated software.

- Kitchen Top CNC KT48 is very intelligent.

- a、It can shows the operator the right placement of the vacuum pods, and of the parts to work.

- b、It has automatic and dynamic compensation to account for the wear of tools, so the machine will always achieve a perfect polish.

- c、Also optional the surface probe, this option allows the machine to work parts with inconstant thickness with the polished side up.

- d、The machine can also optionally mount a tool diameter probing laser, to automatic measure tools diameters.

- e、Other options include the left and right spindle group rotation; this option allows the machine to make polished drain boards for kitchen tops.

- It can import and work with DXF (AutoCAD) files and “G-code” ( RS-274 machine tool programming language) .

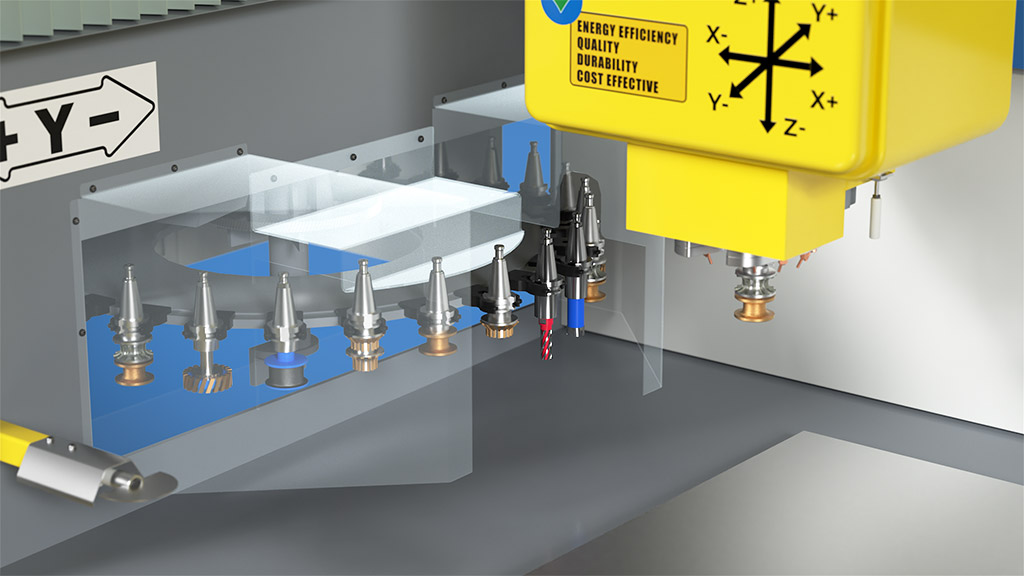

- The machine comes standard with 27 automatic tool change stations on a tool carousel optionally extendable to 108.

- The machine has 4 interpolated axis X, Y (REAL gantry controlled), Z and A (Spindle position control),and the absolute precision of the movements is guarantee by a state of art transmission on linear ball guides, moved by brushless motors through ball screws and a precision of 0.01mm.

- Kitchen Top CNC KT48 has a lot of power, The servo cooled vectorial electric motor has a constant power of 70Nm (highest torque of any stone working center) and is controlled in speed and angular position from 0 to 10000 RPM, it can process stones faster.

- The machine with the optional CAM program is capable of processing complex 3D engraving jobs out of stone blocks like a basin or a bust, the machine can read G-code up to hard drive size with a maximum working speed of 6000mm/min and a precision of 0.01mm.The machine works with standard 3D G-codes, G-codes can be generated from any commercial CAM, the machine is capable of engrave writing, doing bas-relief and so on. The only limit is the capability and the fantasy of the operator.

CNC Controller & Software

Easy to use interface. Imports and works with DXF files and G-Code, but can also do simple cuts in manual mode.

Diameter Probe

The machine can optionally mount a tool diameter probing, to automatically measure tool diameters.

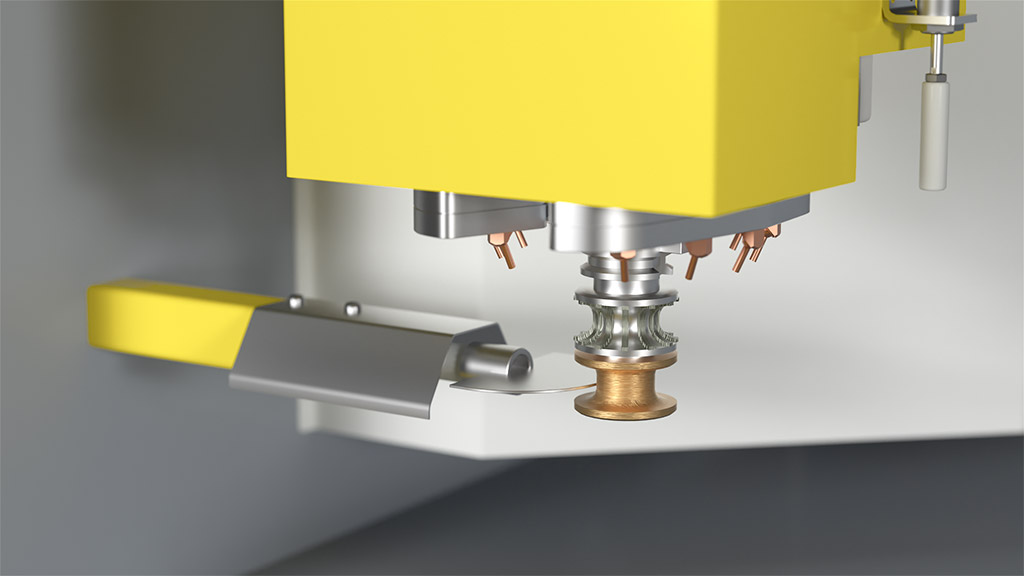

Double Tools

The machines with automatic tool change also support more than one contouring tool mounted on the same cone.

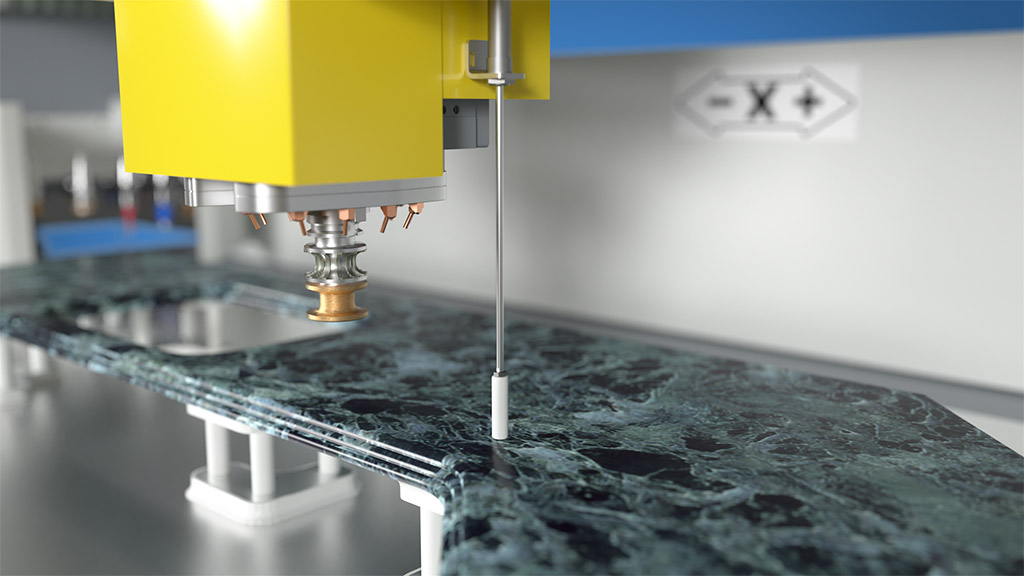

Thickness Probe

An optional surface probe allows the machine to work a slab with inconsistent thickness,while leaving the polished side up.

Automatic Tool Change Stations

The machine comes standard with 27 automatic tool change stations on a tool carousel (optionally extendable to a possible 108.)Technical date

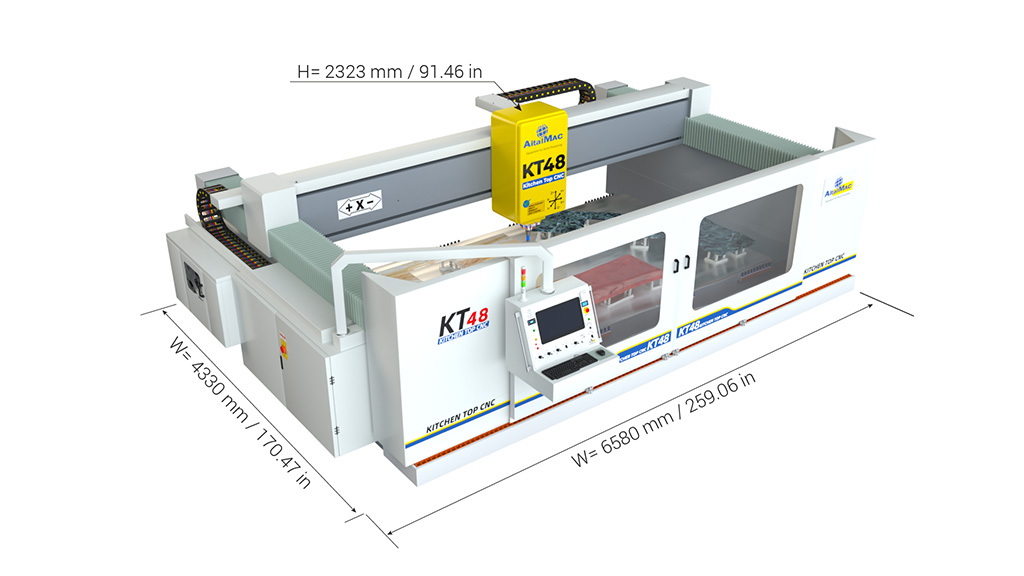

| Overall dimensions | 6580 × 4330 × 2323 mm / 259 × 170 × 91 in. |

|---|---|

| Total weight | 9000 kg / 19841 lbs |

| Max. Install power | 23 kW |

| Linear axis travel (X-Y-Z) | 4540 - 2810 - 460 mm / 179 - 111 - 18 in. |

| Max linear speed (X-Y-Z) | 38 - 38 - 12 m/min / 124 - 124 - 39 ft/min |

| Max. spindle nose to table | 540 mm / 21-1/4 in. |

| Electric spindle power | 15kW(S1) |

| Maximum spindle rotation | 9000 RPM |

| Maximum tool diameter | 120 mm / 4-3/4 in. |

| Tool holder cone | Cone ISO 40 |

| Automatic tool change stations | 27 (54 Optional) |

| Vacuum pump motor power | 1.5 kW |

| Vaccum pump capacity | 0.45 m³/min |

| Air pressure required | 7 bar |

| Water consumption | 20~50 l/min / 5~13 gal/min |