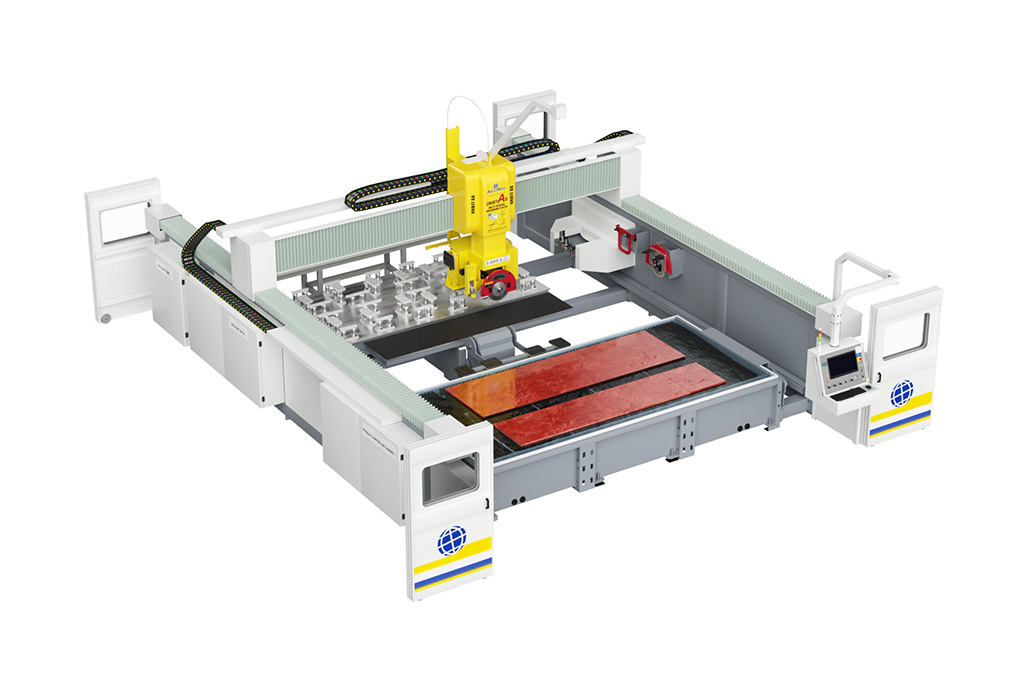

Multi-tasking Machining Center Orbit A8

AitalMAC’s Orbit A8 is the future of kitchen countertops fabrication, it’s the ultimate evolution of the modern fabrication facility. Where in a current countertop manufacturing process multiple machines need to be deployed, which are a bridge saw, a CNC router, an edge polisher, and a waterjet, AitalMAC’s A8 is the all-in-one reliable machine that can do it all, a combination of all of the indispensable machines to fabricate kitchen countertops.AitalMAC’s engineers designed this multitasking machine to be efficient and reliable, testing and evaluating countless different solutions, the A8 incorporates all the best decisions made by seasoned engineers, to create the ultimate all-in-one stone processing center.

The Orbit A8 is a double table 5-axis SawJet with vacuum manipulator, it’s also a full-fledged 5-axis CNC work center and a straight edge polisher all in one!

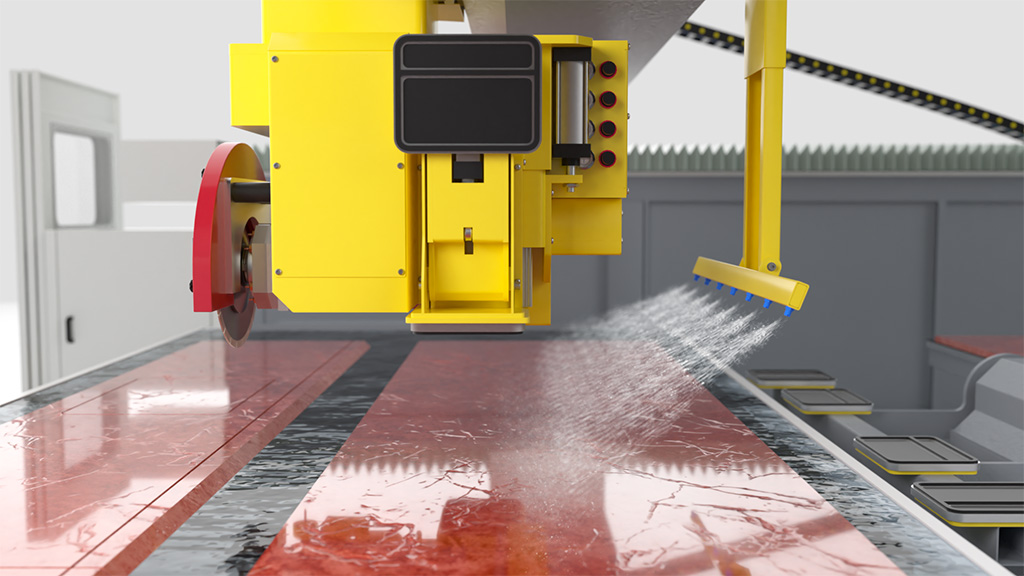

The waterjet technology allows the A8 to process a wide range of materials including ceramic stone, natural stone and sintered synthetic stone.

The easy to program and versatile AitalMAC CAM solution allows for cutting polishing and engraving, which makes the Orbit A8 the ideal solution for all kind of stone fabrication like architectural projects, constructions, funerary and monuments.

AitalMAC’s Orbit A8 will have an unprecedent impact on your shop productivity, all the time associated with planning and moving will be exponentially reduced.

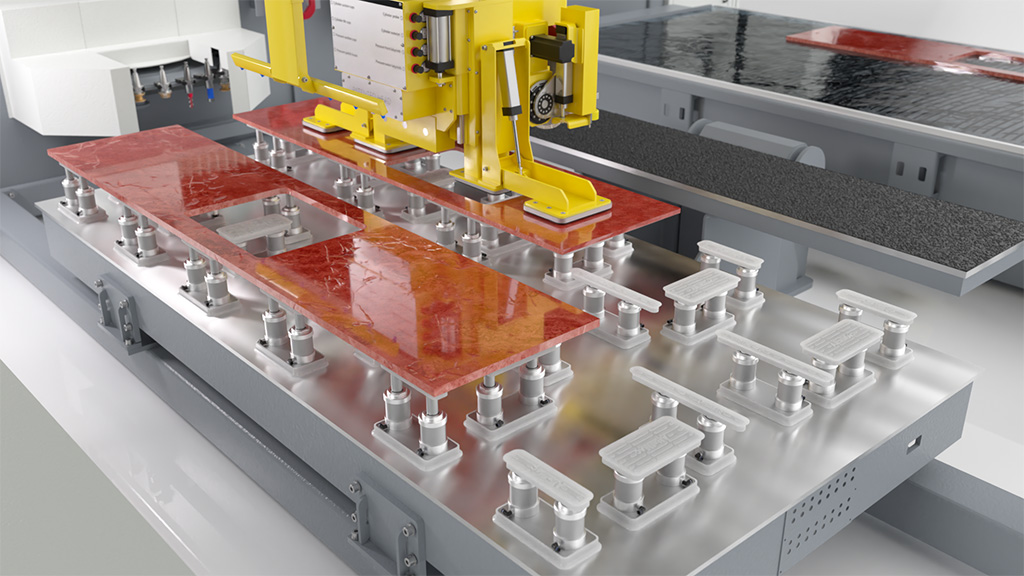

The A8 fabrication process starts with the easy load of the slabs on the tilting table, then the machine produces every straight cut with the saw blade, parts that don’t line up to match will be moved with the vacuum manipulator and then be finished with the saw blade, the waterjet then takes over to finish sink corners, tight curves and other complex cuts. The parts that don’t require finishing can then be unloaded by the machine, parts that do require finishing will be moved to the finishing table (optionally parts can be taken to a flipping station first), this incredible finishing table with completely automatic vacuum pods system will retain the parts, the machine can then change to CNC profiling tools to produce polished edges on the sinks, and also use the three pads polishing system located behind the main motor to quickly polish straight edges, the finished parts will then be unloaded while the next slab will be loaded ready for the next project.

These amazing productivity advancements will skyrocket your fabrication profitability, if you have been searching for the ultimate all-in-one solution for your fabrication shop, look no further, AitalMAC’s A8 is the ultimate all-in-one CNC double table fabrication center.

CNC Controller & Software

Easy to use interface. Imports and works with DXF files and G-Code, but can also do simple cuts in manual mode.

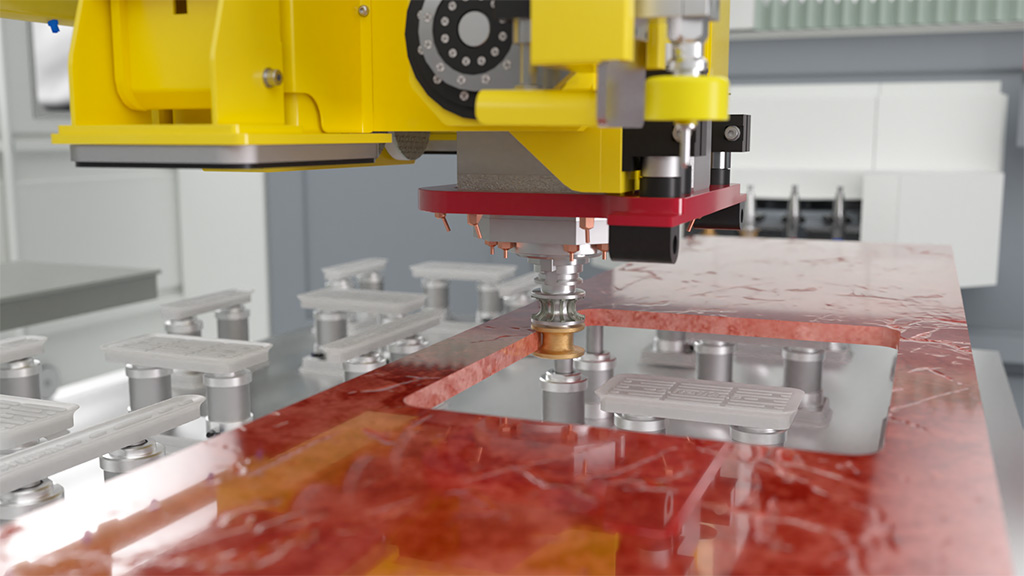

5 axis cutting head and Waterjet

Can miter and interpolate in any direction .

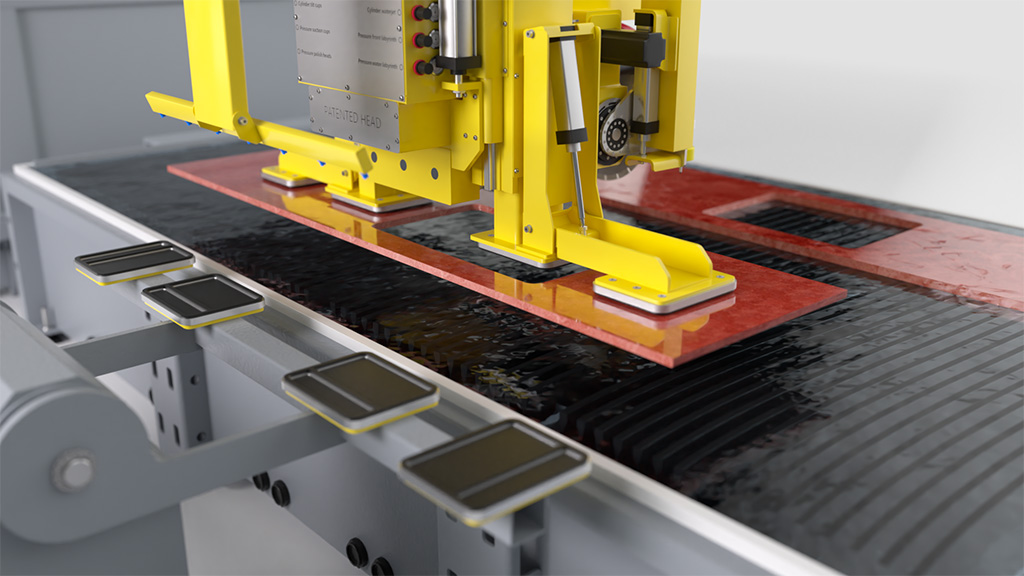

Vacuum manipulator system

The manipulator system has eight vacuum cups, enabling a lift capacity of 500kg / 1100lbs.

Washing apparatus

Included in the machine a slab washing apparatus that is used to wash the stone before the vacuum manipulations.

Auto Table & stone workpiece flipping system

Optionals the Auto Table Covered with automatic suction cups, and flipping system that can flip workpiece to facilitate processing.

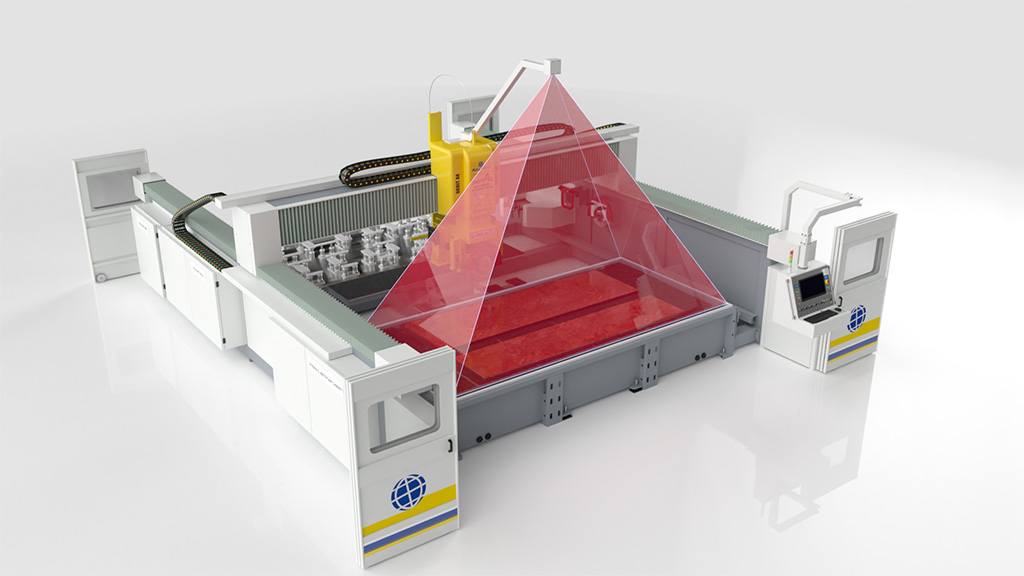

On-board camera

The machine is supplied with an on-board camera with a precision of +/- 5mm. With the camera is possible to snap a picture of the slab, and then import the picture in the program to place your parts avoiding defects.

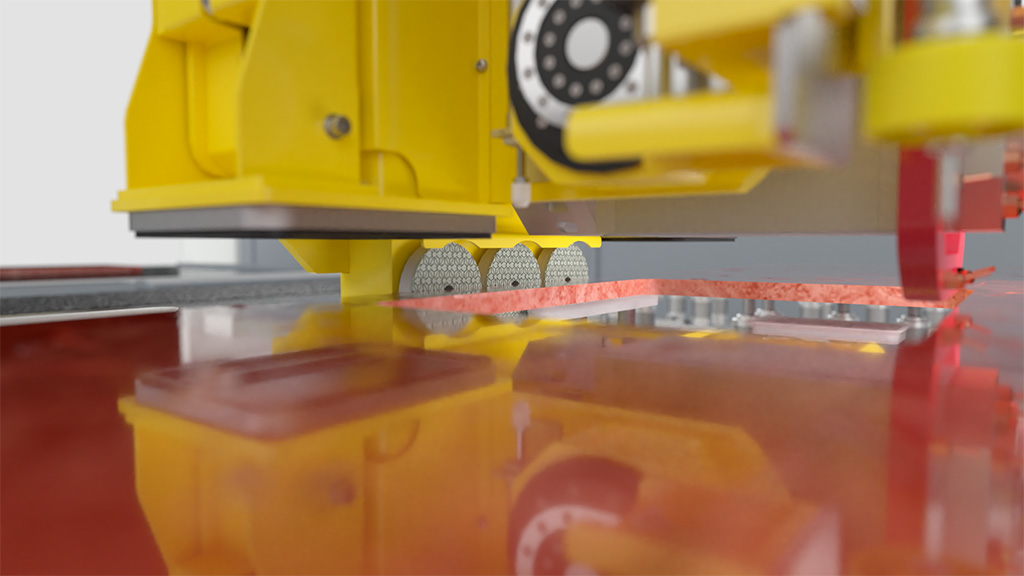

Three edge polisher

Multi-tasking Machining Center can effectively polish the edge of stone

CNC contouring

Multi-tasking Machining Center supports double tools for CNC contouring.

Tilting table

Stone Machining Center Orbit A8 fabrication process starts with the easy load of the slabs on the tilting table.

Laser probe & Stone perimeter probe

The stone probe enable the machine to process the stone more accurately.

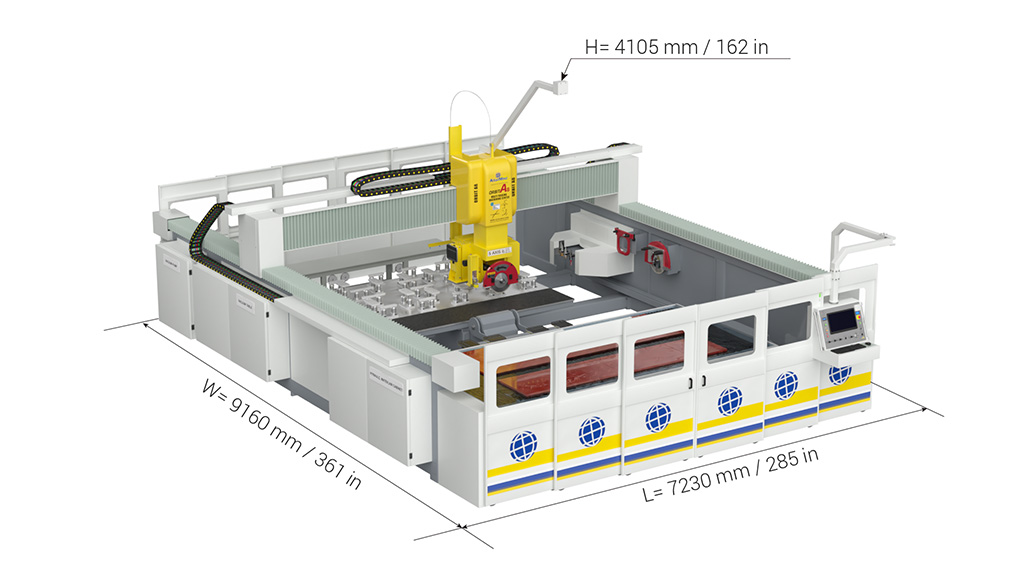

| Overall dimensions | 7230×9160×4105 mm / 285×361×162 in |

|---|---|

| Total weight | 22000 kg/48502 lbs |

| Max. Install power | 26 kW +18 kW(WJ) |

| Sawjet table size | 4410×2100 mm/174×83 in |

| CNC Polisher table size | 3500×1700 mm/138×67 in |

| Linear axis travel (X-Y) | 4300-6680 mm/ 169-263 in |

| Rotary axis travel (B-C-V) | 90°-540°-65° |

| Max linear speed (X-Y-Z) | 50-50-8 m/min / 164-164-26 ft/min |

| Max rotation speed (B&C) | 3600°/min |

| blade diameter | 300-500 mm/12-20 in |

| Cutting disc hole diameter | 50 mm/1.96 in |

| Cutting disc flange diameter | 200 mm/7.87 in |

| Max cut thickness vertical | 100 mm/3.9 in |

| Electric spindle power | 15 kW(s1) |

| Maximum spindle rotation | 9000 rpm |

| Maximum pressure of Sawjet | 60000psi |

| Maximum angle of Sawjet | 60° |

| Maximum diameter of CNC tools | 100 mm/3.9 in |

| Automatic tool change stations | 23 |

| Cutting head Vacuum cups | 8 number |

| Vacuum lift capacity | 500 kg/1100 lbs |