Water Treatment Plant

Water Recycling system for stone and glass fabrication shopsThe system occupies only 2x2 meters, it is capable of clarifying over 300 lt per minute or 100 gallons per minute of sludge.

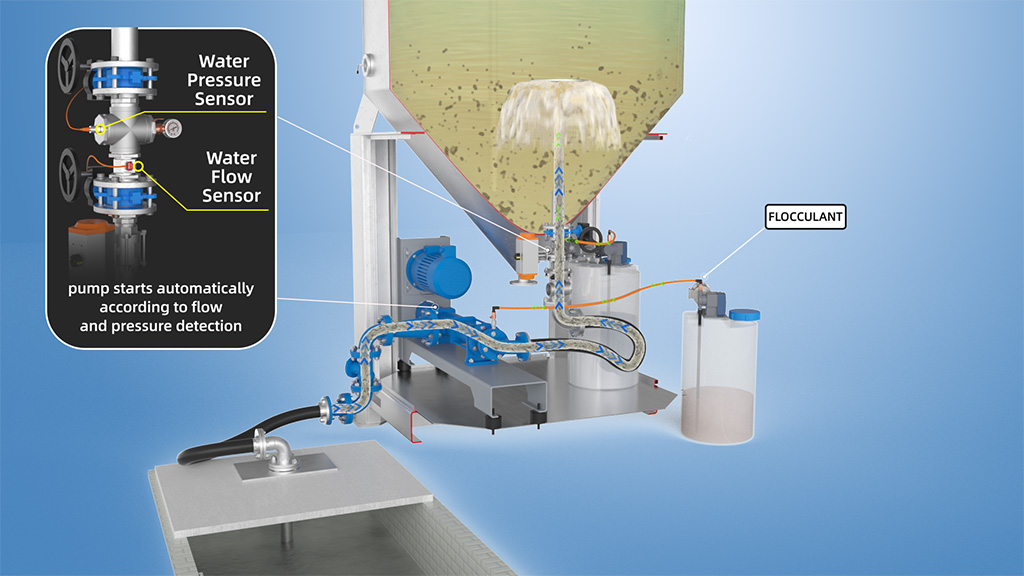

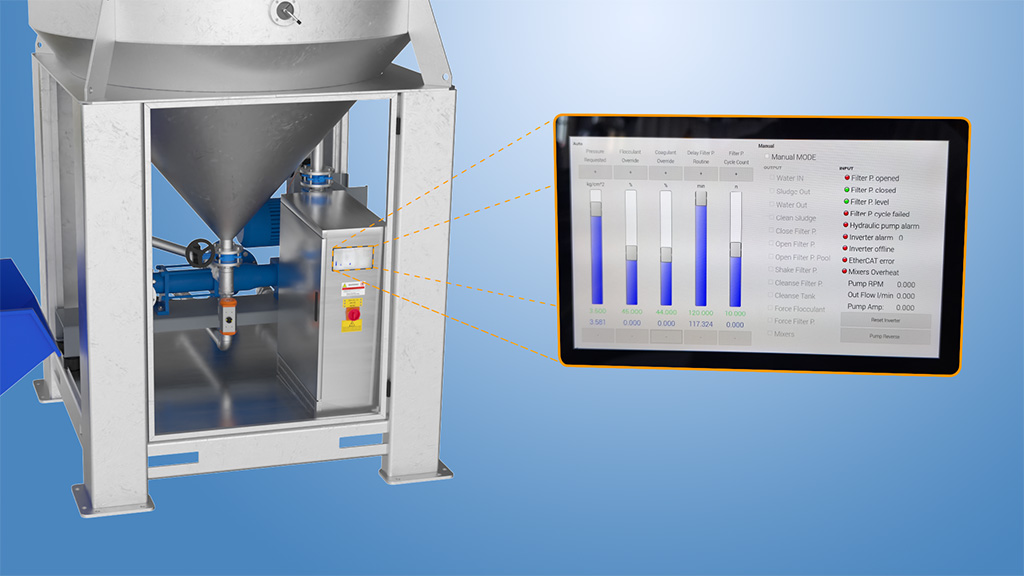

This water treatment plant is equipped with a smart control unit that manages it in all its functions.

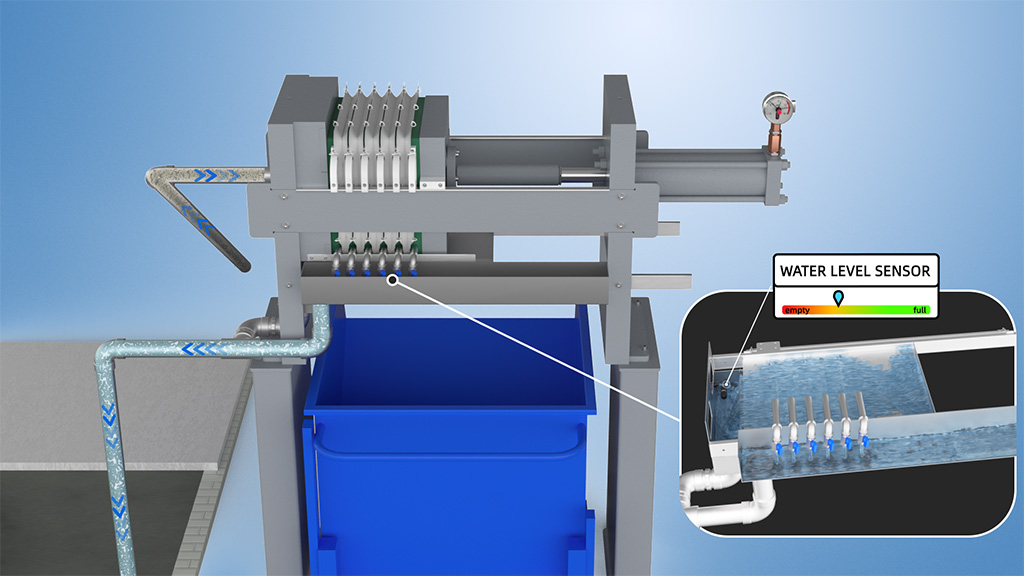

The entire system is pressurized solely by the wastewater suction pump, which is operated by an inverter and dynamically controlled maintaining a constant pressure throughout the system.

The flocculant is dynamically dosed in relation to the amount of water being used.

This system is easy to install and maintain (service)

The operating cost of this water clarification plant is low thanks to dynamic pressure and flocculant controls.

Water Treatment Plant

The flocculant is dynamically dosed in relation to the amount of water being used.

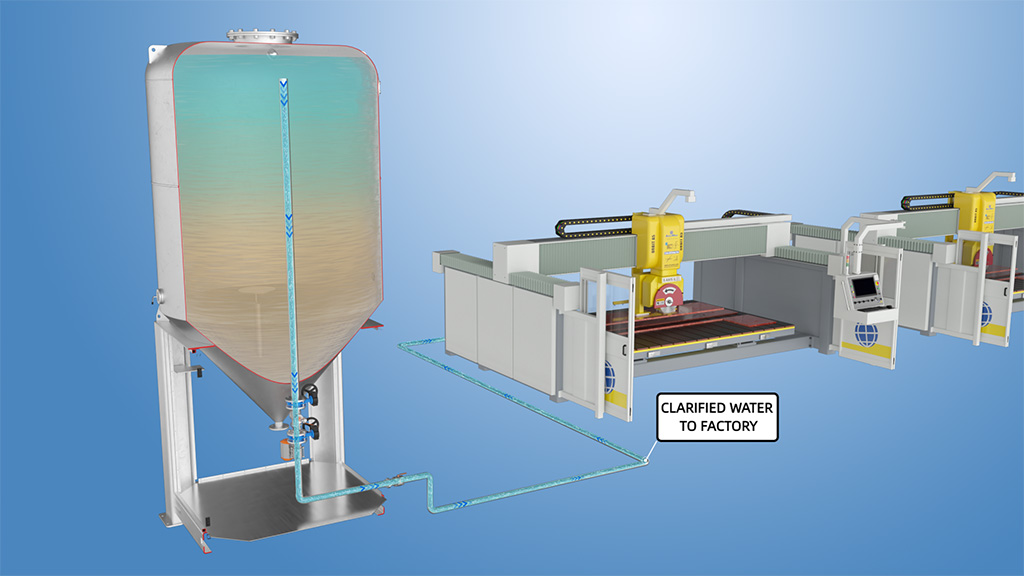

Clarified water to factory

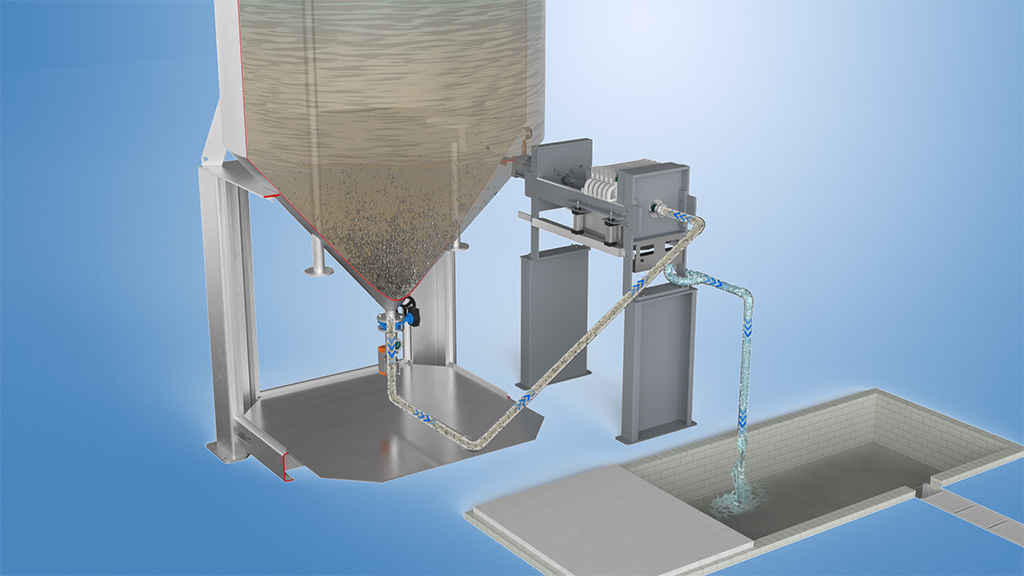

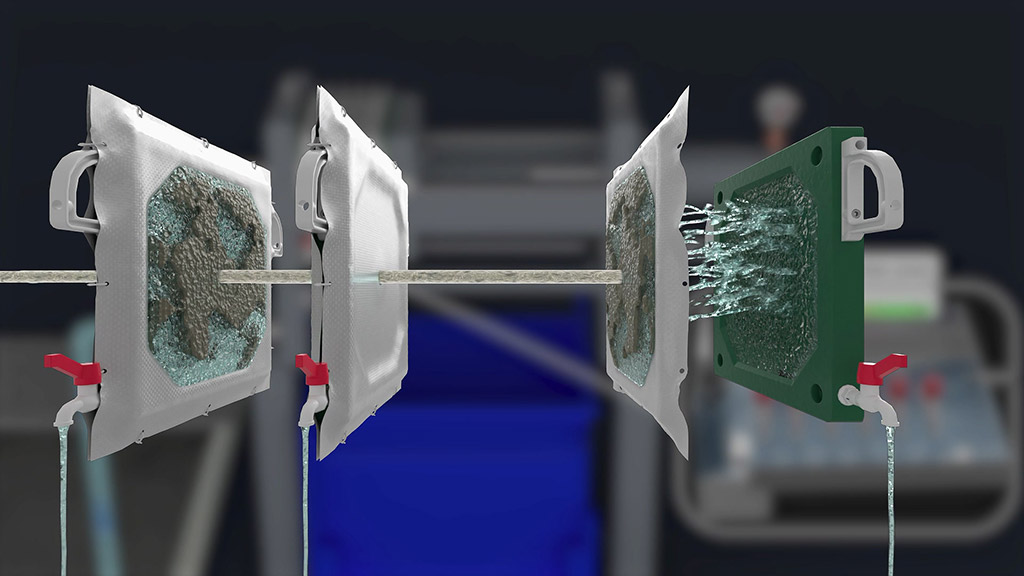

Water Treatment Plant Filter net

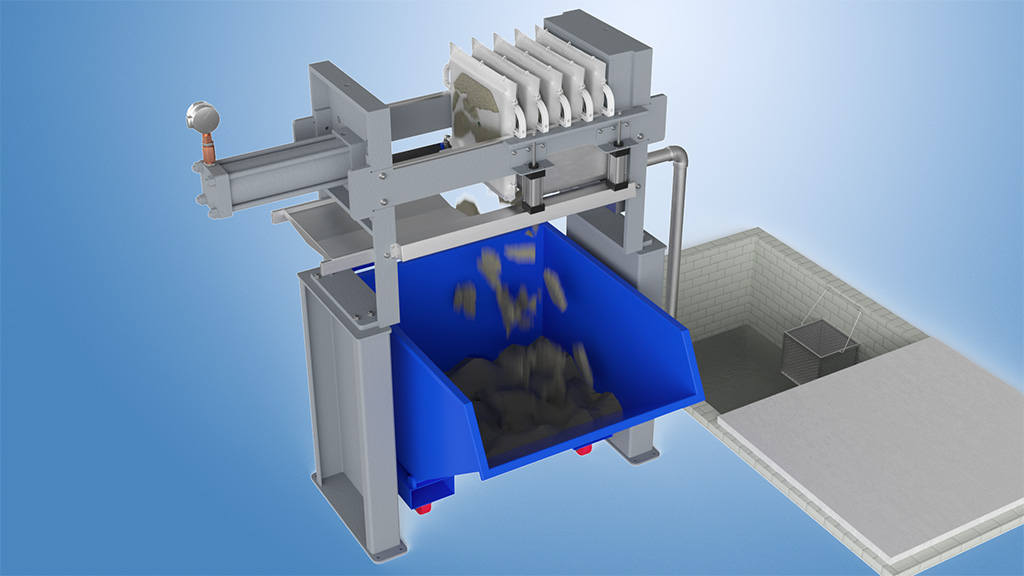

Collect the sludge

Water Treatment Plant CNC